The Buzz on Manufactured

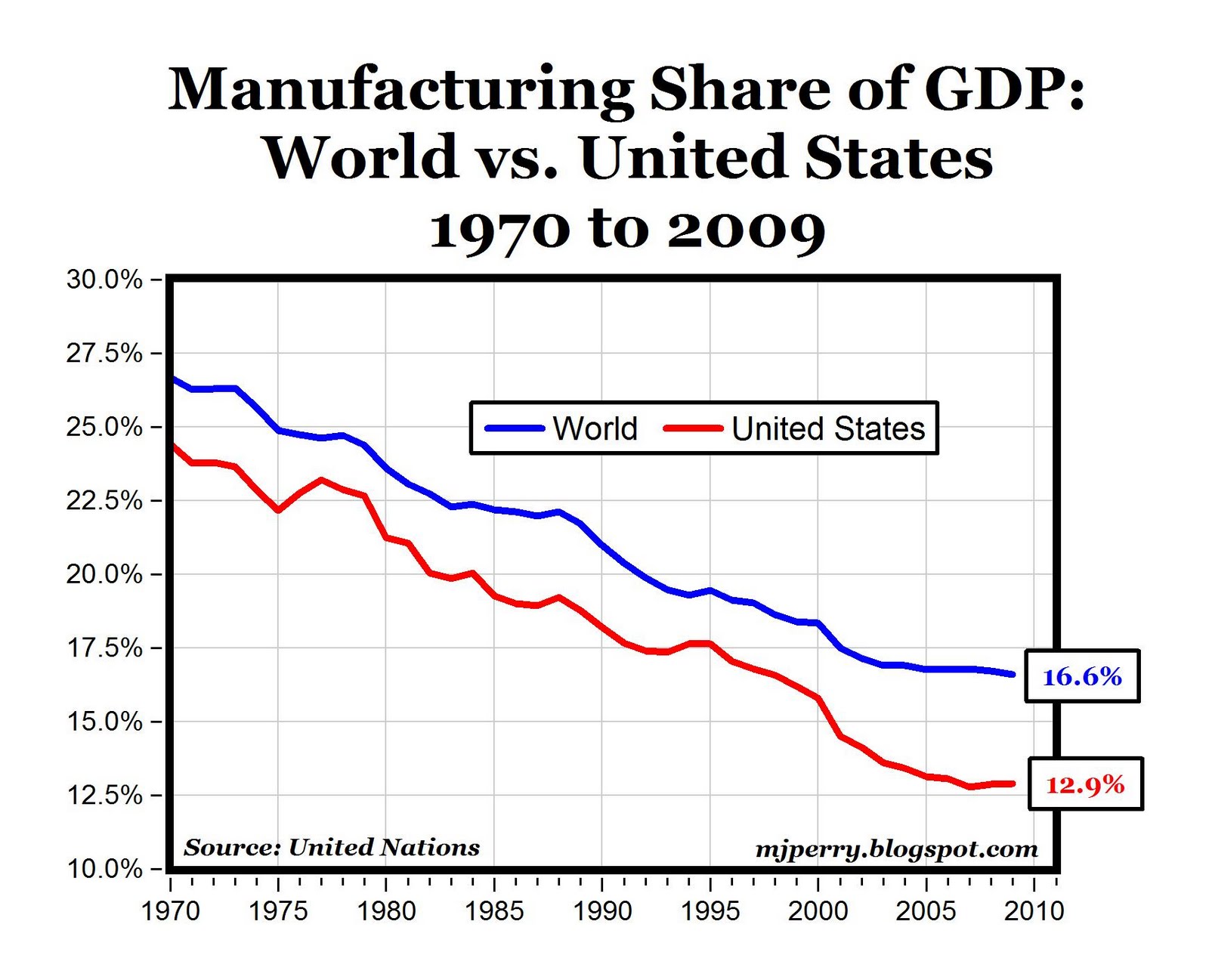

is that our focus now is various. We have carried on to ingenious items that require engineering and sophistication." There is still a role for lower cost production, however that would be served more by near shore countries. Mexico for the United States, Eastern Europe or North Africa for Europe.

Knowledge@Wharton: What are the implications of these altering expense structures for U.S. manufacturers? Rose: In general, it's excellent news. The western hemisphere in basic and North America in specific, is a massive trading block. U.S. makers ought to have a chance to win more business there while continuing to contend on the worldwide phase for high-tech and highly crafted items.

Even if of these longer-term patterns, U.S. producers can't lose concentrate on releasing and incorporating technology, and reengineering procedures to drive productivity gains. That is a place where we have actually seen a lot of slippage in the United States in the last 10 years that requires to actually be re-energized.

As you know, Prime Minister Narendra Modi had actually introduced this program called Make in India. Do you believe initiatives like Make in India and the climb of manufacturing in other parts of Asia have a possibility of being successful? Rose: A lot of people say China is becoming reasonably more costly, and for that reason manufacturing is going to diminish there.

The truth that they are getting more expensive does not spell doom for them. The Chinese consumer market is mushrooming. In a world of regionalizing supply chains, I see Chinese production simply reorienting to make more of what they would have traditionally exported, for their own Chinese customers. In terms of other nations like India, Vietnam and Thailand, there is definitely a lot of opportunity for them.

My clients are significantly thinking about sourcing from them for basic parts. But there are real structural issues there. Several years back, I looked at Vietnam, and it turns out they only had one-twentieth of the port capacity of China. So realistically, how much manufacturing could overnight, or even in the short-term, choose up and move from China to Vietnam? In India, there are documented cases where it has actually taken longer for products to get from the center of the nation to the port in Mumbai than it has for that ship to cruise from the Mumbai port to the United States.

There is a big facilities push across Southeast Asia and South Asia. But it will take a very long time and a lot of investment for them to become a possible replacement for the volume of manufacturing that happens in China. Knowledge@Wharton: Coming back to the U.S., you say that the U.S.

Why do you think this is very important for U.S. producers? "Sixty percent or more of the tasks in a factory can be possibly automated. Therefore, over the long term, the advantage from being a low expense country starts to disappear." Rose: I don't just think it is very important, I believe it is crucial.

The Best Strategy To Use For Us Manufacturing

Jobs go away, or modification, and humans feel left behind. However if we desire to maintain as a production powerhouse, I genuinely see this as the only choice. And the U.S. needs to lead here. It's insufficient to simply let it happen naturally with time. Look at what other nations are doing-- Germany, Japan, and of course China-- they are actively driving advanced manufacturing innovations into their supply bases, into their OEMs.

requirements to actively promote this also. Knowledge@Wharton: Does the U.S. have enough competent employees who know how to deal with these ingenious manufacturing technologies? How serious is the abilities gap and what should be done about it? Rose: We researched this numerous years earlier. As part of this research study, we pulled headings from Germany, from China, from Japan.

And they all state there is a crisis, we do not have sufficient knowledgeable workers. And yes, there is a skills space in the United States, and this will be a substantial challenge and a growing obstacle moving forward. The more intriguing concern is whether it is a relative downside to others.

Nonetheless, we require action here too, especially as we consider the effect of innovation that is gazing us in the face. Government and scholastic organizations have a function, and they need to lean into that. But I believe more than ever, companies need to do that also. For a very long time, companies have treated the manufacturing employees as non reusable, in a sense.

This has got to alter. Employees, especially in an extremely competent manufacturing world, are a real competitive property for a company. What does that indicate? Business require to own the problem, and they require to start to construct tools to grow their own specialists, rotate them as they would executive groups to keep them engaged, retrain them when their job modifications, and not rely on federal or local government assistance or neighborhood college programs and so on.

And everyone else is going to be having a hard time around trying to pick up people on the margins. Knowledge@Wharton: Is that what you imply by a relative disadvantage of the other nations? Rose: Exactly. Knowledge@Wharton: Could provide us some examples of companies in the U.S. that are well positioned for the future in regards to production? What have they done in a different way, and what can other manufacturers learn from their experience? Rose: Let me offer you 3 examples.

The first maker is John Deere. They are making outstanding efforts to integrate innovation both into their items and also into their procedures. They are constructing their labor force in a lot of rural areas where people would typically say it's been hollowed out by previous economic downturns, and maybe the skills do not exist.